UV-Protection Yellow Foil YSA520 self-adhesive

PRODUCT INFORMATION

"UV-Protection Yellow Foil YSA520 self-adhesive"

Lithoprotect® UV-Protection Yellow Foil YSA520 self-adhesive

GENERAL INFORMATION

The self-adhesive UV-protection yellow foil YSA520 was specially developed for UV-photo-sensitive applications and blocks UV-radiation below 520 nm. The UV-protective film YSA520 consists of yellow-dyed cellulose triacetate and is coated on one side with a permanent dispersion glue, so that it can be laminated bubble-free over the entire surface of all solid interior surfaces. By full-surface bonding as on windows, room dividers and screen elements, it provides a reliable UV-protection even in demanding applications. Our self-adhesive YSA520 UV-blocking filter is widely used in photolithography, PCB and microelectronics manufacturing, photoresist preparation and the handling of photoresists and diazo films. Even in the pharmaceutical industry and laser technology, our self-adhesive YSA520 UV-blocking filter allows a reliable protection against UV radiation below 520 nm.

MAIN FEATURES

- Blocks wavelengths below 520 nm

- Outstanding optical purity

- High adhesion

- Long-term UV-stable

- High inherent scratch resistivity

TECHNICAL DATA

- Bond strength immediately: ~ 7.5 N / 25 mm

- Bond strength after 7 days: ~ 15 N / 25 mm

- Adhesive: Acrylic-dispersion adhesive

- Cover: PE cover, red plaid in 10 mm grid

- Max. width: 1,15 m

- Length: Material sold by meter. Further dimensions on request.

- Temperature range during application: 15 °C

- Temperature range: -30 °C to +80 °C

- Installation: Indoor

CHEMICAL CHARACTERISTICS

The laminated yellow foil YSA520 is resistant to most oils and greases, gasoline and aliphatic hydrocarbons. The surface of the yellow film is partially dissolved or swollen by hydrochlorofluorocarbons, ketones or aromatic solvents, which can affect the optical properties. The UV-protective foil YSA520 is waterproof for a short time when glued on. Long-term exposure to moisture can lead to reduced adhesive strength and subsequent detachment of the foil.

TRANSMISSION

The transmission characteristics of our self-adhesive UV-protection film yellow YSA520 are very close to our former yellow foil Y520, and were specially adapted to the stringent quality requirements in the area of the yellow rooms in photolithography and micro-electronics industry. According to the semi-logarithmic graph shown below, the transmission at 450 nm is about 0.0001 %, which means that it has decayed to a millionth of a part at this wavelength. If you compare our film with other “yellow” foils, we recommend to ask for a semi-logarithmic transmission plot.

Semi-Logarithmic Transmission

Linear Transmission

The transmission spectrum is not to be understood as a specification, but as an exemplary measurement on a Lot.

FIRE BEHAVIOR

The laminated self-adhesive UV-protection yellow film YSA520 is self-extinguishing.

STORAGE

Under proper storage conditions of 5 - 25 °C and a relative humidity of 30 - 60%, the UV-protection film YSA520 has a shelf life of up to one year. To avoid pressure points, we recommend a standing or hanging storage.

PROCESSING

The yellow foil YSA520 can be glued with our mounting fluid DXMF301 easily and bubble-free on any smooth and solid indoor surfaces. Detailed information is available in our assembly instructions for self-adhesive UV-protection yellow film YSA520.

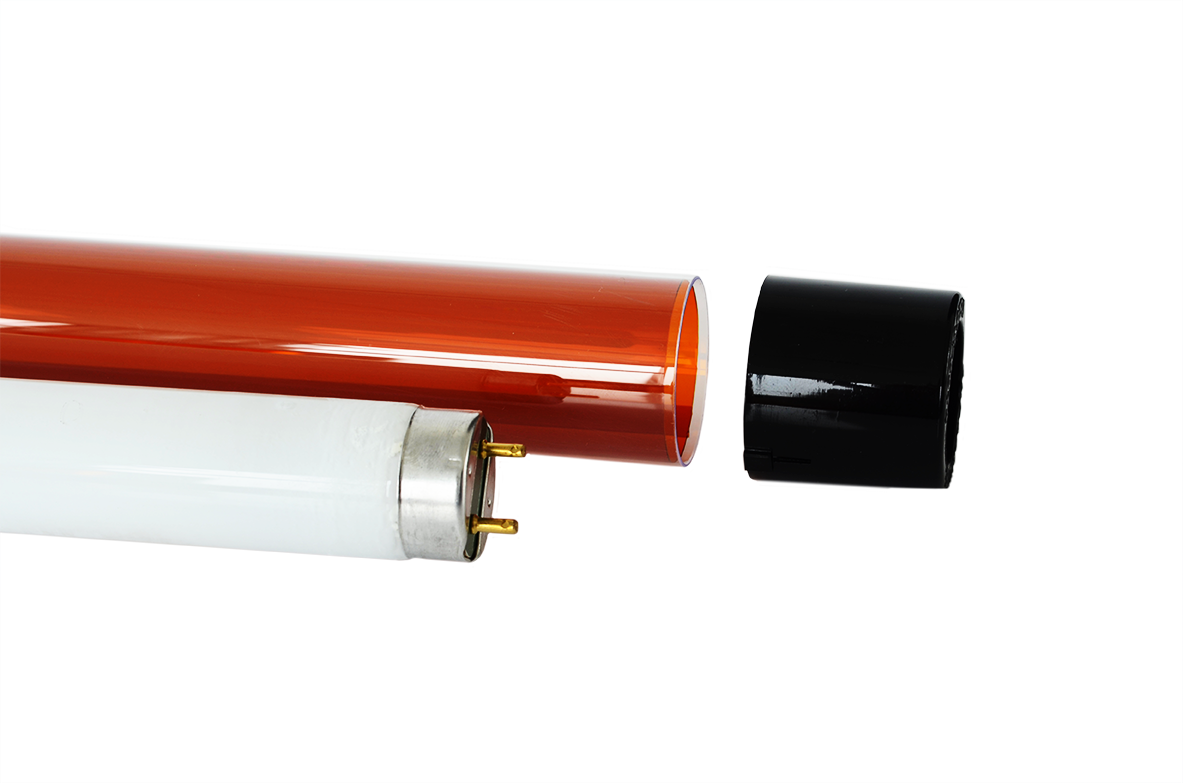

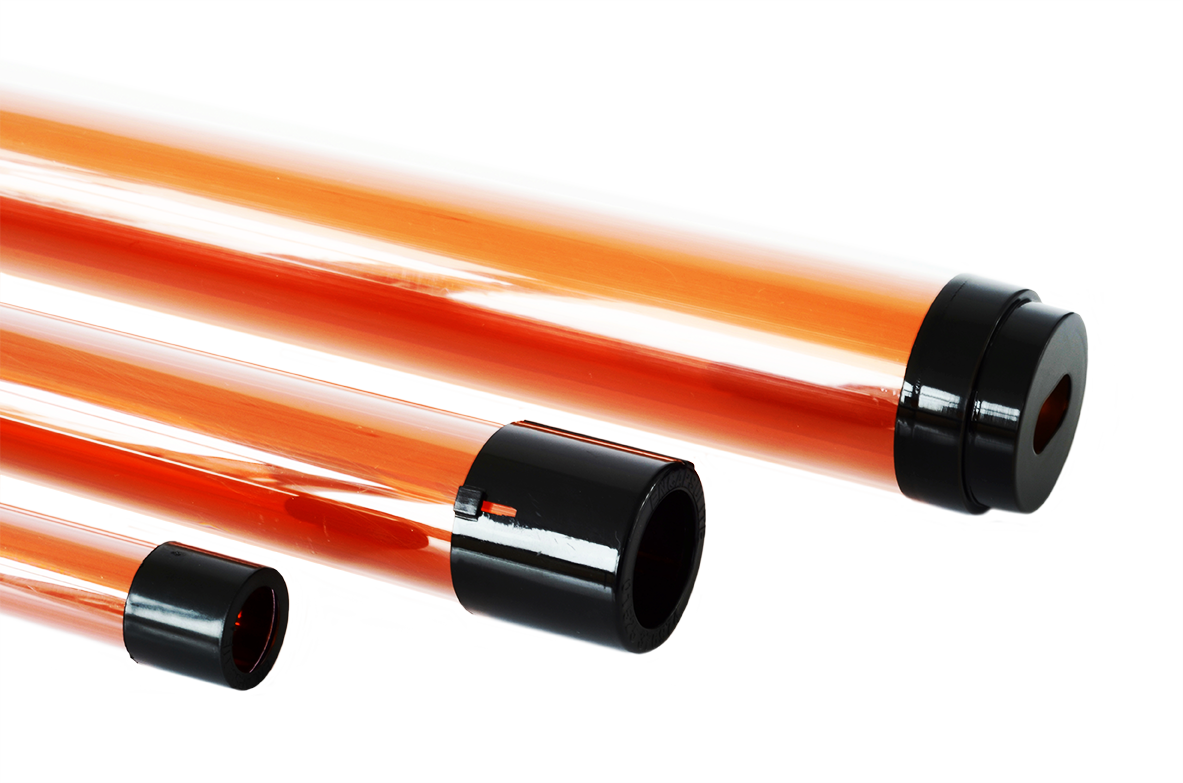

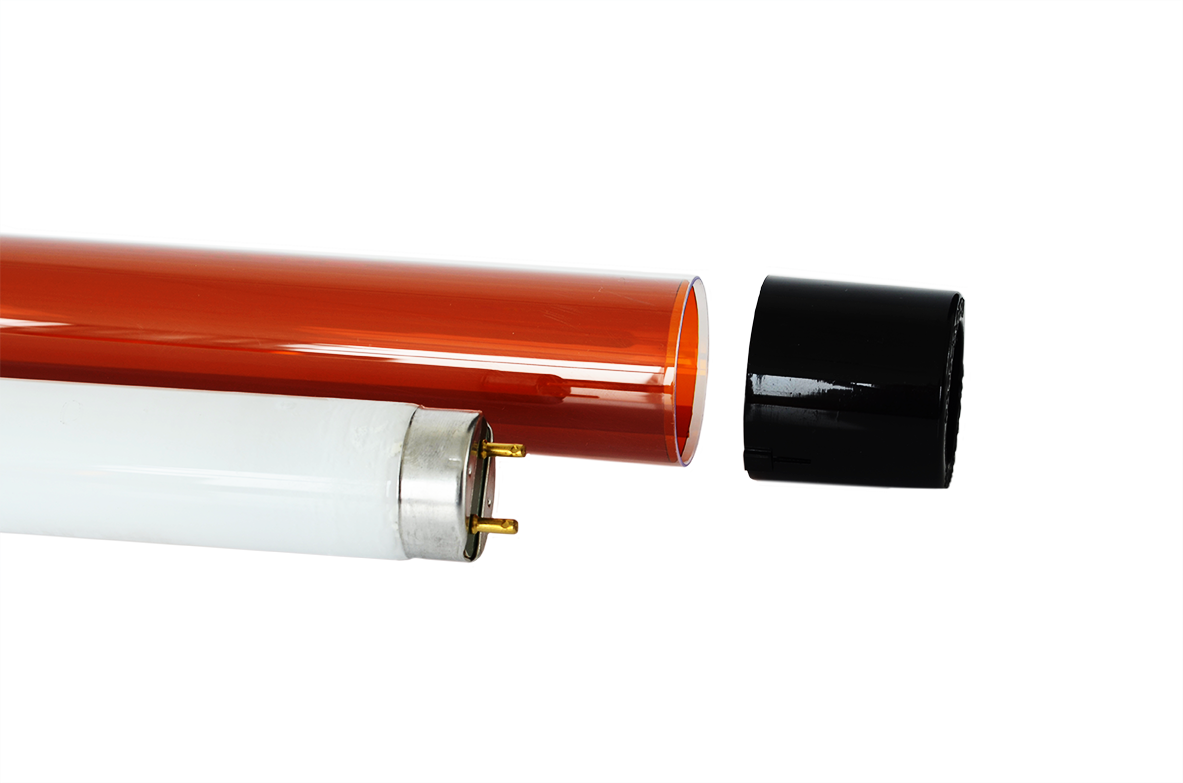

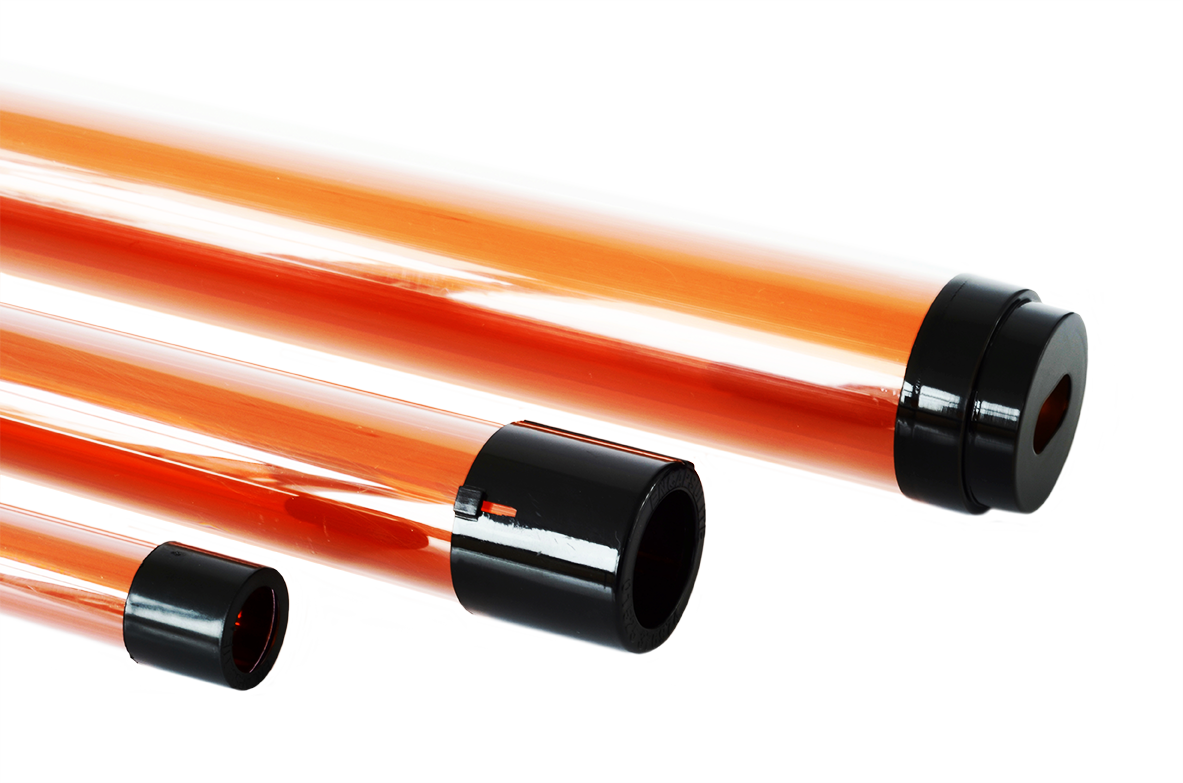

For filtering fluorescent tubes, we recommend our specially designed polycarbonate sleeves. Here, our UV-protective film Yellow Y520 is already incorporated, so you can cost-effectively “upgrade” standard white fluorescent tubes for your yellow light application.

FURTHER INFORMATION

Technical Datasheet:

Technical Data UV-Protection Yellow Foil YSA520 self-adhesive english

Technisches Datenblatt UV-Schutz Gelbfolie YSA520 selbstklebend deutsch

Application Note:

Installation Instruction english

Montageanleitung deutsch

Maintenance Instruction english

Pflegehinweis deutsch

Installation Instruction Video

Montageanleitung Video

NOTE: All data and information relate to the best of our knowledge and are based on measurement and experience. It remains in your responsibility to check the suitability of our yellow foil for the intended use of it. Our products are regularly quality-tested and further developed. We therefore reserve the right to adjust without additional information, the chemical composition or physical characteristics of new knowledge.

Related products

Accessories